Light Manufacturing

Light Manufacturing Adjustments (LMF 5)

Processing a Light Manufacturing Order

Light Manufacturing has to be activated via the System-Wide Settings - Part 1 (Green Screen menu option SET 4).

This application combines Order Entry and Bill Of Material concepts, to process orders for light manufacturing and assembly of finished goods. The primary concept in manufacturing is finished goods being manufactured from components. This application relieves component inventories and adds to finished goods inventory.

Finished goods items: New finished goods items are entered as regular items except that they MUST include policy code S2, to indicate the item is primarily manufactured to order. The standard costs entered for these items should be the ‘standard cost of manufacturing'. This standard cost should include all components and processes used to create the item, including labor. Finished goods items do not have to be completely precise. For example, for laminated panels, you can enter a unique item number for each type of board, board thickness, and class of laminate, but not for each specific combinations of items (which could be countless). As orders are taken, specific colors and sizes may be specified. No changes to the item file would be required.

Component items: Component items are entered as regular items in the item file. No special codes are needed, as they can be sold as is, or as a component of a finished goods item.

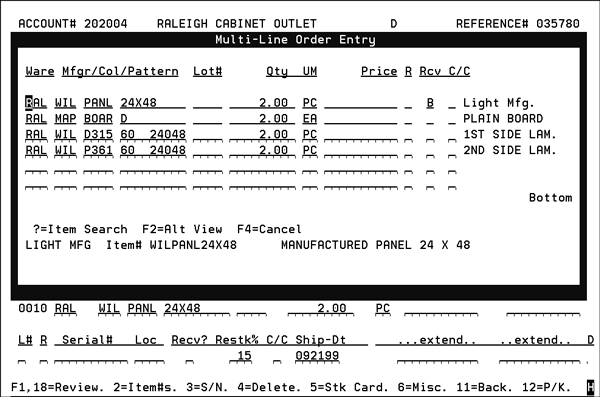

Bill-Of-Materials File: A BOM file entry is required for all finished goods (policy S2) items. The BOM should include an entry of each component that needs to be adjusted from inventory to create the item. Items in the BOM may be overridden. Include the most applicable (popular) component items, and then the user can override to specific choices when the item is ordered. All items should be entered with a quantity ratio of component quantity to finished goods quantity, when applicable. The above screen is an example of a light manufacturing bill-of-material. The only thing that differentiates light manufacturing Bills-Of-Material from other Bills-Of-Material is the policy S2 in the item file of the finished good items.

The Light Manufacturing and Assembly application combines Order Entry and Bill Of Material concepts, to process orders for light manufacturing and assembly of finished goods. The primary concept in manufacturing is finished goods being manufactured from components. Option 5 - Light Manufacturing Adjustments relieves component inventories and adds to finished goods inventory.

Notes about Making Adjustments:

- Labor items are included in the light manufacturing process update. Essentially the labor order line is deleted off the order and accounted for in the final assembly item number.

- All the component lines have to be at an X status (indicating complete) before the final assembly can be completed. If all the component lines are not at an X status you will receive an error message. Use menu option LMF 9 to update the line statuses to X.

- Inventory adjustments can be run against items with an item policy code of S3 (bordered rug).

- Serial numbers can be automatically assigned to manufactured items. Unique prefixes and suffixes can also be assigned to help identify manufactured items. Automatic assignment of serial numbers can be set at:

- The Global level via the System Wide Setting - Light Manufacturing Options.

- At the SKU level via the Stock Keeping Unit File.

- If the SKU file is set-up to for automatic serial number assignments the global setting must also be set-up. The SKU settings override the global settings.

The first screen in the process is shown below.

- If only an order number is keyed, all finished goods items on that order, followed by their components are displayed. The user can update as needed from that list.

- If an order number plus an item number is keyed, then all manufactured products on that order which contain the item number as a finished good or a component are displayed. The user can update as needed from that list.

Press Enter to access the order details. This screen displays the goods on the order that have been or are being manufactured. The user enters the quantity actually manufactured in the QTY-To-Mfgr field. The user can also enter a serial number, and can optionally enter a bin location.

The Adj Cd setting allows you to override the global setting established via the System Wide setting - Light Manufacturing Options.

It is recommended that the serial number be either a simple default or a meaningful entry, such as part of a sidemark, the order number, or part of the customer name.

The user can only adjust the finished goods quantity, and then the program automatically adjusts the components. If any components are found which are still on back order, the adjustment may cause that inventory to go negative. This is allowed, although the components on back order should normally be filled prior to this screen being used. The user can enter a positive or a negative (reversing previous incorrect entry) quantity, it must not exceed the quantity in the Qty-Left-To-Mfgr column.

The order will be split if the quantity being adjusted is less than the quantity left to manufacture. It duplicates all of the finished goods, component and message lines associated with the line being adjusted onto a free span of line numbers on the same order. The new lines contain the quantity not adjusted.

After making the adjustments in the Light Manufacturing system, the assembled item gets entered into inventory.

Options

Printing a Shipping Label (Option P)

F12 Function to Update Shipping Information

Printing a Shipping Label (Option P)

The P option allows you to quickly and easily print a shipping label. When a P is entered into the Opt field, enter the Order/line number, number of labels, and printer ID.

F2 =Alt View (Update Cost)

The option Allow Cost Adjustment for Authorized Users in the System Wide Setting - Light Manufacturing Options must be activated in order for a user to update costs.

Press F2 to display the alternate view which is where you can update the cost of the item being manufactured/assembled.

The editable cost entered into the Cost field is the unit cost from the Cost File.

The cost will be increased by the freight component from the Cost File when the finished good material is adjusted into inventory.

The Suggested Cost (Sgst) is the total cost of the components of the manufactured/assembled item.

If you change the Cost, the new cost only applies to that serial number (in this example AX000251DE).

F12 Function to Update Shipping Information

This function accesses the Update Order Status and Shipping Data screen. You can use this screen to inquire on and/or update the status and shipping dates of the manufactured and component items.

- To change the status of one of the items, move the cursor to the Status field of the corresponding line item and enter the letter of the new status. Press Enter. Repeat for all the line items you want to update.

- To change the status, ship or order dates of all lines on the order, move the cursor to the respective Update Entire Order fields at the bottom of the screen.

Press F7 to return to the Light Manufacturing Adjustments screen.

Order Status Codes

The following is a listing of system defined Order Status Codes. User defined codes are not included in this table.

- A - Assembled, staged in warehouse, and ready for pickup or delivery. This code can be used for any type of order.

- B - Open back order. Back orders have this status assigned at the time the order is entered. Manufactured/Assembled items are automatically assigned to a B status.

- D - Order has been delayed and will miss the original ship date. This code is usually used for purchase orders and back order.

- F - Future or future order. This code is usually assigned during Order Entry, but can be changed using this program.

- H - On hold. Held but not a confirmed order. This code is assigned at Order Entry, but when the order is confirmed, use this program to change the code to K (confirmed) or O (open).

- J - Purchase order has been rejected by supplier. This status code is for purchase orders and back orders. J is used primarily by EDI when the supplier is automatically updating your system with the status of your purchase orders. Status J indicates the order can not be serviced.

- K - Order and ship dates are confirmed. This code is usually used for updating back orders, purchase orders, and holds.

- L - A bar code label has printed for this order. This code is automatically applied to a line when a bar coded pick label is printed. This code can also be applied manually using the Update Order Status and Shipping Data Program. The L status can be extremely useful for blanket orders, and retail sales in which the consumer is picking up parts of an order on different days. A partial pick list can be printed based on status code. For example, you could enter the L status code on the lines you want released for picking and then print a partial pick list for the L status lines only. For users of our Bar Code Pick Label Pool, whenever a label is selected to print from the pool, that order or line is updated to status L.

- O - Open order. A blank in this field also indicates an open order. This status is assigned automatically when the order is originally entered and no other status is noted.

- P - Partially received from supplier, now in-house. Also use this code to indicate that the paperwork has been received but not the goods. This code is generally used for import or large purchase orders that have a long receiving process (more than one day).

- R - Received from supplier, now in-house. This code is automatically assigned when back orders are filled using the Pre-Receive and Back Order Fill system. You can also assign this code here.

- S - Shipped to or picked up by customer. This code should be assigned immediately after material is shipped or picked up.

- T - Purchase order in transit from supplier, or ready to be picked up at supplier's location. This code should be updated only for purchase orders. Using it for customer orders could confuse the order with transfers.

The following series of screens takes you through the entire life of a Light Manufacturing order.

- Enter the quantity of the finished goods you want to order.

- Press Enter. The light manufacturing bill-of-material is displayed. You may change quantities and items, as needed. All items under the top item (which is the finished goods) are considered manufacturing components.

- Make any needed corrections and press Enter. The next screen to appear uses ISO to check inventory. ISO will always back order the finished goods, which will be manufactured. All components use normal ISO logic. They may be transferred, back ordered, etc., like any other items. All components are priced and costed at zero. They are to be adjusted, not sold. The price of the finished goods is inclusive of all components.

- Press F1 to review the order. The order entry review screen displays light manufacturing orders as shown below. A dash next to the line number indicates a component.

- The screen below shows the user at the manufacturing plant indicating that the 2 PC were manufactured. All components are adjusted out of inventory. Finished goods are added.

- The screen below is displayed after the adjustments have been made.

When invoiced, the finished goods and components are shown on the invoice, but only the finished goods are actually added to the Invoice file and to sales history reports. The components are included in the inventory history files as adjustments with code R (remanufactured).